CAPSTIAN TECHNOLOGY

- Application

- …

- Application

CAPSTIAN TECHNOLOGY

- Application

- …

- Application

CAPSTIAN TECHNOLOGY

Flyer Active Dual Bobbins Pay-off

It is mainly used for continuous, noiseless and smooth pay-offconductors during high-speed extrusion production of wire insulation layers.

Structural Features

- Consisting of two parabolic pay-off barrels made of cast iron or stainless steel.

- The inner surface of the barrel is polished and has a longitudinal groove which allows the conductor to pass from one pay-off barrel to the other, completing continuous reel changes and ensuring.

- Pay-off speed can be up to 1000 m/min.

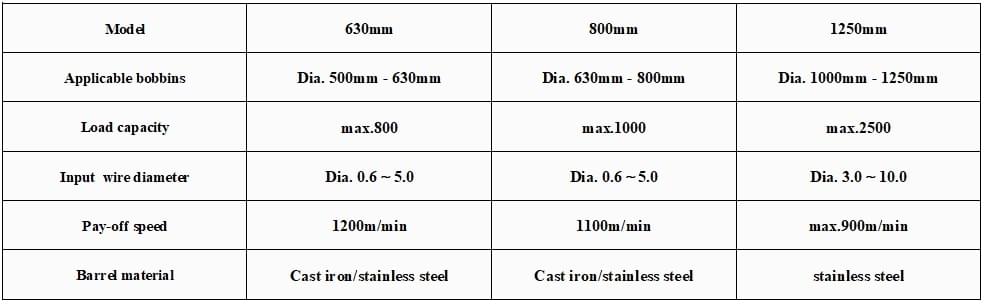

Technical parameters

- Applicable wire diameter: Dia. 0.5-6.0mm.

- Applicable wire reel: Dia. 500-630x80 (inner hole) x400 (outer width), can also customized.

- Max loading capacity: 800Kg.

- Pay-off way: electric drive, Φ700mm swing ring pay-off.

- Pay-off motor power: 1.1kw frequency conversion control.

- Loading and unloading bobbin: electric lifting, cart-type input bobbin.

- Lifting way: reduction motor.

- Double cone made of all stainless steel.

- Tension rack: 5.0kg magnetic powder brake, tension digital display adjustable. Flow fan cooling.

- Wire break detection: proximity switch detection.

- Guide wire rack: Dia. 300mm, wheel groove sprayed with ceramic treatment.

Operationg feature

- After the empty machine wiring is confirmed, test run, test the inverter and tension controller, and the output is normal.

- Move the cart and adjust the center axis height to load the wire reel.

- Install the swing ring and confirm that the front locking nut is locked.

- Move the cart, load the barrel, and lead the wire through the wire setting mold and the straightening table.

- Wind the wire through the tension frame and adjust the tension.

- According to the production line speed, set and adjust the frequency of the ring release. When one axis is almost released, pull out the bottom line head, pass through the barrel connecting groove, and connect it firmly with the release head of the other barrel reel.

- When one bobbin is released, it automatically switches to the other axis to release the wire, and so on, to achieve continuous production without stopping.

500-630mm Flyer Dual Bobbins Pay-off

Electrically adjusted magnetic brake that allows the unloaded wire to enter the extrusion head at the desired tension.

High-Speed Precision Dual Flyer Pay-off

Here are some additional models or variations of Dual Flyer Pay-off, each with its own unique features and benefits.

This model is designed for industries that demand extremely high production speeds without compromising on precision.

Contact us

We are dedicated to providing you with the highest quality Dual Flyer Pay-off solutions. If you have any inquiries, require further information, or would like to discuss a potential partnership, please feel free to contact us using the following methods.

34-401 Yangming street, Yuyao city, ningbo city, zhejiang province, china+86-18606615951

Chinese Cable Extrusion Line

Chinese Single Twisting Machine

Chinese Wire Bunching Machine

Address: No.401, #34 Bingjiangxincun,Yangming Street, Yuyao, Ningbo,China

Proudly built with Ningbo Capstian Technology Co.,Ltd.