Go Back

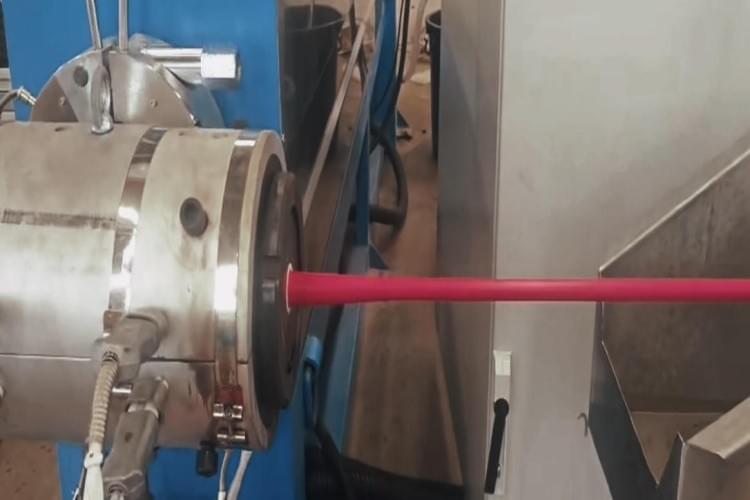

Solar Cable Production Machine SJ-70+120 Cable Extruder Machine

You can find reliable solar cable manufacturing equipment manufacturers and suppliers who provide all the cables needed to manufacture photovoltaic installations: rooftop, floating, and photovoltaic power plants.

More Details

Solar Cable Production Machine SJ-70+120 Cable Extruder Machine

1.Application;

Our PV solar cable extrusion line is specifically designed for the extrusion of photovoltaic wires, catering to wire sizes ranging from 4 mm² to 6 mm²,

Handing solar cable extruder is an efficient equipment specially designed for the production of photovoltaic cables.

2.The main technical parameters

- Conductor size range:

- Co-extrusion: Ø3.0- Ø40mm,

- Single extrusion: Ø20- Ø100mm #75

- Co-extrusion: Ø5- Ø50mm,

- Single extrusion: Ø30- Ø110mm #120

- Finished cable diameter:

- Ø5.0- Ø50mm #75

- Ø30- Ø110mm #120

- Host machine screw rod diameter: Ø70mm Ø120mm

- Screw rod L/D:25:1

- Main machine screw rod speed:

- 0-90r/min #75

- 0-65r/min #120

- Main machine max extrusion capacity:

- 180kg/h #90

- 440kg/h #120

- Linear speed:0-80m/min Co-extrusion 0-300m/min #75

- Max traction force:2400kg

- Pay-off bobbin size:PN800-PN1600

- Take-up bobbin size:PN800-PN1600

- Power consumption:235KW

- Water consumption:Circulation

- Operator:1 or 2

- Working voltage:3 phase -5 wires. AC380 (±10%),-50HZ, according to customer’s standard.

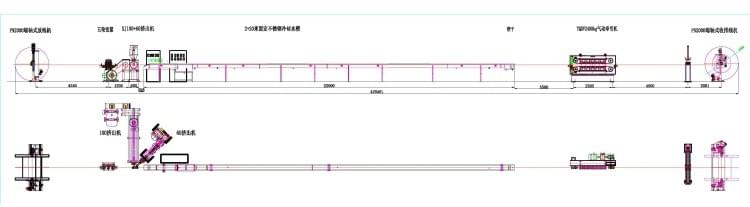

3. Main Components

PN1600 Column type pay-off machine

- 1600kg belt pneumatic caterpillar (5 pairs of cylinders)

- SJ-75/25D extruder

- Ø50mm Crosshead (adjustable)

- SJ-120/25D extruder

- Ø60 and Ø100mm Crosshead (adjustable)

- Crosshead trolley

- Automatic hopper and loading system

- 2m moveable +20m fixed Stainless steel water trough

- High efficiency Blow Drying device

- Ø500mm Double wheel type capstan

- 2400kg belt pneumatic caterpillar (6 pairs of cylinders)

- Guide wire stand and meter counter

- PN1600 Column type take-up and traverse line machine

- Electrical control system of unit

4. Main extruder parameter:

- SJ75/25 Extruder

- Screw diameter: Ø75mm

- Screw L/D: 25:1

- Screw form: Efficient gradient screw.

- Screw rod rotation speed: 0-90r/min

- Max extruding output: PVC: 160kg/h

- Main motor power: 37kW ACmotor, controlled by speed control system

- Screw material: 38CrMoALA, Surface nitriding treatment, nitriding depth 0.5-0.8mm, Surface hardness≥HV840

- Screw rigidity≥HV940

- Screw cooling: center hole water cooling.

- The crosshead: three piece Haff clamp with full tools, easy to operate.

- N. of heated/cooled zones: 6 zone. Head section 2, eye mold section 1, head lock section 1, material barrel section 6 section. six high-power DF series axial cooling fans

- Machine barrel material: 38CrMoALA,Surface nitriding treatment, nitriding depth 0.5-0.8mm,

- The barrel adopts electric heating: the cast aluminum heating ring has good heating and insulation performance.

- The gearbox: the gears are all with 40Cr, the gear surface is anneal and tempered with high frequency, the surface hardness is hrc50-55, the shaft is tempered with #45 steel,

- Temperature controller:RKC

- The temperature controller adopts intelligent electronic display calculus temperature controller, the temperature can be automatically adjusted between 0-399 ℃, and the temperature control accuracy is ± 2 ℃

- Ø50mm Round jacket crosshead

- Adjustable crosshead, right angle circular structure

- Heating of cast aluminum

- Max diameter of mold sleeve: Ø45mm, max extrusion core:Ø40mm

- The cross head material is made of steel, with surface nitriding treatment, nitriding depth of 0.5-0.8mm, and surface hardness ≥ HV840

- Features: When replacing the mold core or sleeve, there is no need to remove the mold core rod. After adjusting the eccentricity at low speed, the concentricity remains unchanged when the speed increases to normal production speed, and the eccentricity is required to be less than 15%,

- Equipped with a trolley, easy to move

- SJ120/25 Extruder

- Screw diameter: Ø120mm

- Screw L/D: 25:1

- Screw form: Efficient double BM+mixing customized screw, one low smoke and halogen-free screw each.

- Screw rod rotation speed: 0-65r/min

- Max extruding output: PVC:440kg/h

- Main motor power: 132kW ACmotor, controlled by speed control system

- Screw material: 38CrMoALA, Surface nitriding treatment, nitriding depth 0.5-0.8mm, Surface hardness≥HV840

- Screw rigidity≥HV940

- Screw cooling: center hole water cooling.

- The crosshead: three piece Haff clamp with full tools, easy to operate.

- N. of heated/cooled zones: 6 zone. Head section 2, eye mold section 1, head lock section 1, material barrel section 6 section. six high-power DF series axial cooling fans

- Machine barrel material: 38CrMoALA,Surface nitriding treatment, nitriding depth 0.5-0.8mm,

- The barrel adopts electric heating: the cast aluminum heating ring has good heating and insulation performance.

- The gearbox: the gears are all with 40Cr, the gear surface is anneal and tempered with high frequency, the surface hardness is hrc50-55, the shaft is tempered with #45 steel,

- Temperature controller:RKC

- The temperature controller adopts intelligent electronic display calculus temperature controller, the temperature can be automatically adjusted between 0-399 ℃, and the temperature control accuracy is ± 2 ℃

- Ø100mm Round jacket crosshead(2 pcs: one small and one big)

- Adjustable crosshead, right angle circular structure

- Heating of cast aluminum

- Max diameter of mold sleeve: Ø70mm, max extrusion core:Ø65mm

- Max diameter of mold sleeve: Ø105mm, max extrusion core:Ø100mm

- The cross head material is made of steel, with surface nitriding treatment, nitriding depth of 0.5-0.8mm, and surface hardness ≥ HV840