CAPSTIAN TECHNOLOGY

- Application

- …

- Application

CAPSTIAN TECHNOLOGY

- Application

- …

- Application

CAPSTIAN TECHNOLOGY

Building Wire Extruder Line

Application:

Suitable for PVC and PE etc. plastic extrusion, mainly used for power wire, computer wire, insulated wire sheath, building wire etc. production. Equipment constitute: It is composed of double spools pay-off (Japanese style), straightening machine, mainframe, main control cabinet, water trough, accumulator, caterpillar, linkage wire cutting machine, etc. Optional active pay-off, copper pre-heater, talc applicator, low smoke halogen free specialized screw, low-density screw, high-density screw, laser diameter gauge and PLC computer all-process control.

We offer a variety of options for your cable manufacturing

These machines can be selected according to requirements: automatic feeding machine, granule dryer, metering color machine,

outer diameter measurement and control, inkjet machine (laser, ink) frequency spark testing machine and other auxiliary machines.

Layout to Show Main Components of Wire Insulation Line

Building Wires insulation lines suitable for several thermoplastic compounds such as PVC, PE, XLPE and LSHF

How to Making/Manufacturing For Building Wire?

Capstian Tech provides building wires shortens manufacturing lead times and decreases work in progress:

- Drawing annealing: Not provide

- Conductor stranding: 630 wire high speed bunching machine

- Insulation extrusion: 70+35/50+70 high speed wire extrusion machine

- Cable forming machine: Cantilever single twist machine for multi insulation core

- Coiling: Semi-automatic coiling machine

- Packing: Automatic coiling,packing, filming, labeling machines

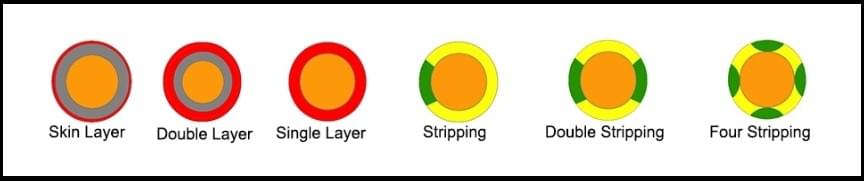

Multiple fuction of our wire insulation machine

Optionally the insulation line can be equipped with a co-extruder for color skinning & stripping purposes.

Customers Feedback

Fully automated, easy to operate, and with 24-hour guidance services, customers can rest assured

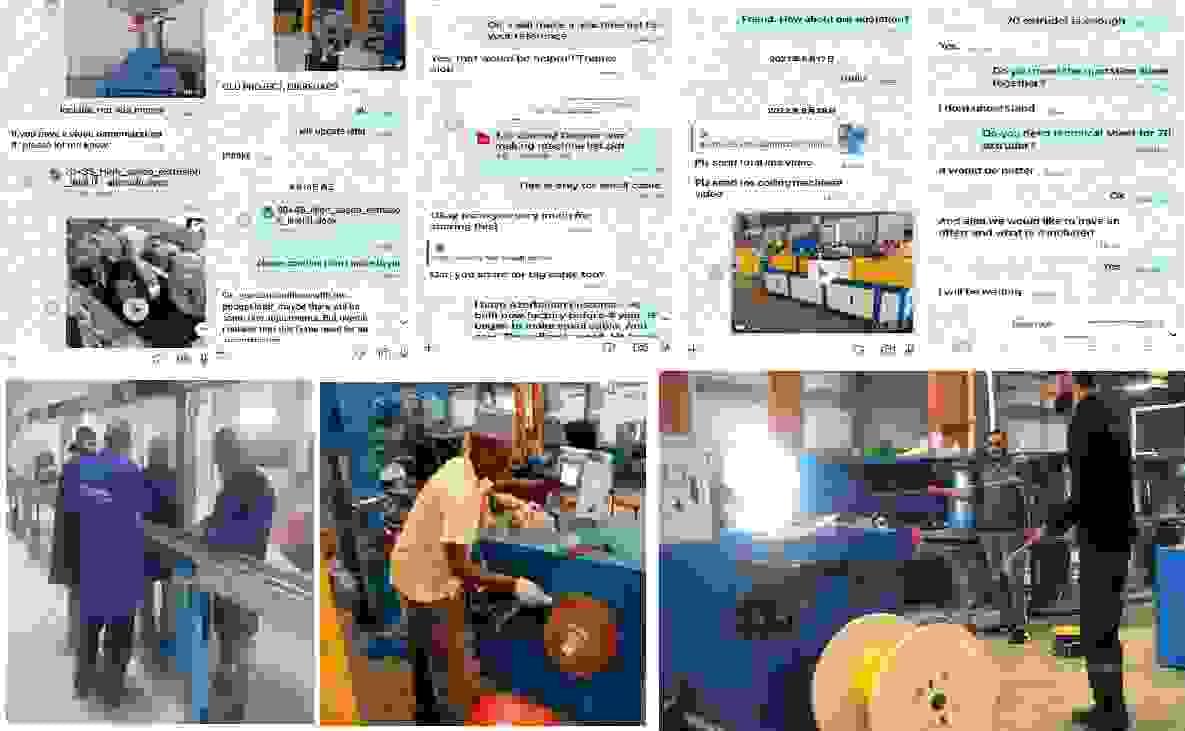

Your Top Building Wire Extruder Manufacturer

CAPSTAN's extruders have been very popular recently and have been recognized by many cable factories.

What questions of building wire and cable extrusion line?

When a customer requests a building wire cable extrusion line, they typically focus on production efficiency, product quality,

cost-effectiveness, and compliance with industry standards. Below are the key questions they may ask,

along with recommended responses to address their concerns professionally.

What is the maximum production speed (m/min) for building wires?

Can this line process both PVC and XLPE insulation? How do you prevent material degradation or bubbles?

How much power does this line consume? Are there energy-saving features?

Does this line meet international standards (IEC, UL, BS, VDE)? Can it print markings compliant with regulations?

What kind of technical support do you provide? Is there a warranty?

What’s the total cost, and how long is the delivery time?

Chinese Cable Extrusion Line

Chinese Single Twisting Machine

Chinese Wire Bunching Machine

Address: No.401, #34 Bingjiangxincun,Yangming Street, Yuyao, Ningbo,China

Proudly built with Ningbo Capstian Technology Co.,Ltd.