CAPSTIAN TECHNOLOGY

- Application

- …

- Application

CAPSTIAN TECHNOLOGY

- Application

- …

- Application

CAPSTIAN TECHNOLOGY

Double-layer Double Color Co-extrusion Extruder Line

Application: Suitable for PVC, PE etc. plastic extrusion, mainly used for power wire, computer wire, insulated wire sheath, building wire etc. production.

Equipment constitute: It is composed of double head pay-off rack ( Japanese style), straightening machine, mainframe, main control cabinets, basin, accumulator, tractor, take-up machine etc. Optional active pay-off rack, copper pre-heater, powder machine, low smoke halogen free specialized screw, low-density screw, high-density screw, laser gauge tester and PLC computer process control.

Extrusion Machine Range & Output Capacity

High Speed Wire Co-Extrusion Line

Advantages of Our Wire Extrusion Line:

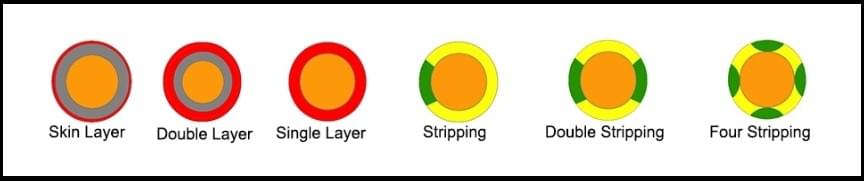

Single Layer, Single Layer+Color skin, Double Layer+Color Skin Three Layer Co-extruder

High capacity

Building a wire extrusion line with continuous extrusion capability can significantly increase production speed and meet the needs of large-scale production.

Flexibility

Ability to handle a variety of materials and specifications, adapt to different types of cable structures, and enhance the versatility of the line.

Green and efficient

Low energy consumption technology, in line with modern environmental protection standards, reduces the impact of the production process on the environment.

Intelligent control system

Equipped with an intelligent control system to achieve real-time monitoring and adjustment, reduce manual intervention, and improve production efficiency.

Precise temperature control system

Precise temperature and pressure control systems ensure product uniformity and stability and reduce defect rates.

Technical support and training

Provide comprehensive technical support and training services to ensure that users can operate efficiently and solve production problems.

Layout of High Speed Cable Co-extrusion Machine

Breaking Down the Components of a Wire & Cable Extrusion Line

Multiple fuction of our wire insulation machine

Optionally the insulation line can be equipped with a co-extruder for color skinning & stripping purposes.

Enhance Your Production Capabilities

It’s with this in mind that we actively contribute to the success of our customers by offering sustainable cost saving solutions. The modern Capstian wire extrusion machinery minimises the consumption of raw materials while enabling the use of recycled materials.

Customer satisfaction is our greatest pursuit

Our focus on advanced cable and wire processing ensures that you can achieve optimal performance,

enhanced productivity, and a competitive edge in your manufacturing operations.

View Our Cable Extrusion Machinery Technical Parameter

Want to see our latest developments?

High quality service and quick support are in our DNA;

Not only do we provide high quality wire extrusion equipment, we also offer you full support.

FAQs

High efficiency extrusion line is used for extruding the insulation and sheath of wire and cable.

What is the speed of extruder line?

What brand of main motor and electrical for this high speed extruder?

Does extruder barrel and screw treatment by nitrided?

What causes uneven surface of extruded wire?

What kind of heating method do you use for the crossheadachine head?

How much surface area can be achieved when two colors are co-extruded?

Chinese Cable Extrusion Line

Chinese Single Twisting Machine

Chinese Wire Bunching Machine

Address: No.401, #34 Bingjiangxincun,Yangming Street, Yuyao, Ningbo,China

Proudly built with Ningbo Capstian Technology Co.,Ltd.